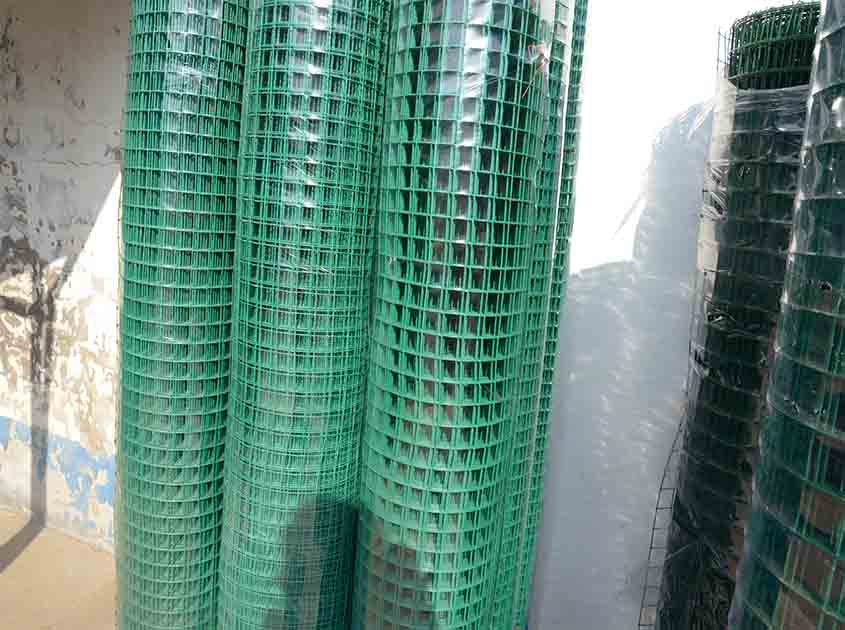

Welded wire mesh rolls: a key role in the welding process

In modern welding process, welded wire mesh roll plays an important role. As a welding auxiliary material, welded wire mesh roll not only provides stable welding support, but also can improve welding quality, improve work efficiency, and provide safety guarantee. This article will explore the key role of welded wire mesh roll in the welding process, and introduce its importance from many aspects.

Welded support and stability:

The welded wire mesh roll is used as a supporting material in the welding process, which can stabilize and position the welding workpiece. The welder can place the welding material or workpiece on the welded wire mesh roll, and the stability of the welding position can be ensured through the support and fixation of the mesh. This helps reduce displacement and deformation during welding, improving welding quality and accuracy.

Splash Protection and Splash Control:

Sputtering and splashing during welding are common problems that can lead to poor weld quality and make subsequent processing more difficult. By placing welded wire mesh rolls around the welded area, the spread of sputtering and spatter can be effectively prevented. The mesh structure of the welded wire mesh roll can intercept and capture molten metal particles, reducing their scattering, thereby protecting the surrounding environment and the welding workpiece.

Weld quality control:

Welded wire mesh rolls can also provide quality control in the welding process. By selecting the appropriate welded wire mesh roll specification and size, the shape and size of the weld seam during the welding process can be controlled to ensure the consistency and reliability of the weld seam. The welded wire mesh roll can also provide support and protection for the weld seam, prevent collapse and air holes during the welding process, thereby improving the quality of the weld seam.

Security and personnel protection:

During the welding process, safety is paramount. Welded wire mesh rolls not only provide welding support and stability, but also act as a protective barrier to protect welders from molten metal splashes and sparks. By properly placing the welded mesh roll, sparks and molten metal can be guided into the welding area, reducing its harm to the surrounding environment and personnel.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China